New Solutions & Updates / Chiara Cattaneo I July 2017

14Just arrived and already been photographed…

“In order optimize our laboratory safety conditions we have just purchased a new forced ejection exhaust hood, ARES model, CE compliant (2006/42/CE). It is equipped with a steel structure, silk-screened tempered glass panels and fireproof wooden shelves. The new hood will allow us to safely conduct aging tests in water, oils and other solvents, thanks to the CE compliant electrical exhauster, which allows the disposal of fumes produced during the tests, avoiding the diffusion of vapors and gases, reducing the risk of inhalation by the operator. It is equipped with electrical and water connections, with water taps controlled from the outside, together with a large work surface that will allow us to place two thermostatic baths, one of which is due to arrive in the next few days. This new acquisition will enable us to increase and refine tests and evaluations in a secure and constantly improving laboratory. ”

– Chiara Cattaneo | R&D Department

Exhaust hood is just one of the first steps in order to optimize and make our new LAV.EL. Lab the most complete possible.

Production, production and again production…

The production department is being constantly updated. In July we purchased two new machines: two brand new 4 nozzles ENGEL and a new Sig-Mac for nitrogen deburring.

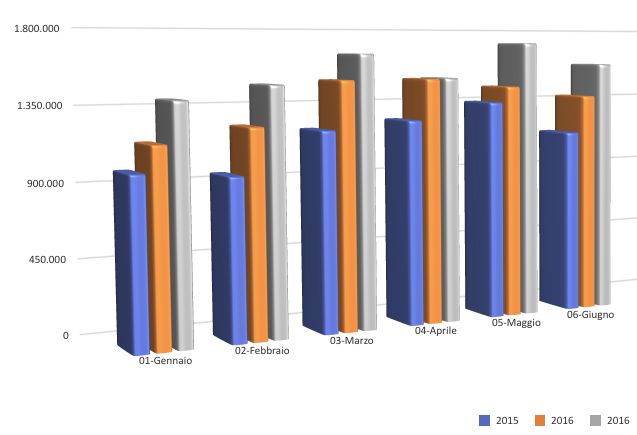

2017 Turnover

We never stop growing! Not only we improve year by year, but we are reviewing our approach to the market, too. Our aim is to strengthen the performance of our commercial network in order to achieve the following goals:

– Manage the relationship with customers to increase their satisfaction;

– Reclassify products to strategically position them on the market;

– Boost sales to increase the turnover.

Since January our monthly turnover has been increasing, due to a better “approach” of our commercial network towards the specific needs of our customers.